Background

From 5000 years ago metal castings have been produced. Iron casting is about 1000 years old. Since the beginning of the 20th century the fast growing casting industry needs more and more high precision and high efficiency.

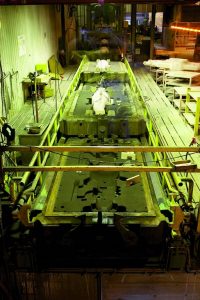

The accuracy of castings depends very much on the process. The use of lost moulds based on organic binders like phenolic resins for sand gives high quality, high productivity and low problem rates.

Use of phenolic resins in the foundry industry

Since about 1948, Phenolic resins are used as organic binders in the so called Croning or Shell Molding Process (invented 1943 by Johannes Croning) for series production of lost molds. In this process, sand is coated with about 2% phenolic novolac and cured at 250-280°C in the presence of hexamethylenetetramine. This process is highly important until now.

Phenolic resins (Resols) are also used in the Hot-box-Process and in low temperature curing processes like Phenolic-no-bake, PUR-cold-box, Ester curing no-bake, MF-cold-box, CO2-resol cold-box.

Phenolic resin coated sands are applied for the production of cores and molds to achieve, in an economical way, castings with high surface quality, excellent mechanical properties, good reproducibility and excellent dimensional stability. Other advantages are short hardening time, a good hardness of cores and shells and a good breakdown capability of cores and shells.

Trend

The trend for the use of phenolic resins as binders is saving energy, short curing times, low consumption of resin, high mechanical strength of the mould and minimization of emissions.

The phenolic resins could be individually tailored for each customer regarding processing or product and cost performance. Phenolic resins are environmentally, and optimized well advanced in terms of all HSEQ aspects.

Final products

The final products from the foundry we can find in our daily life: e.g. as parts of cars, trucks, aircrafts, wind power plants and simply in pumps that we use in our house or in the garden.