Due to ever increasing energy prices, growing environmental concerns and depleting fossil energy resources, state legislators, environmental groups and the public in general are demanding improved performance of insulation materials used in construction. Mineral wool insulation products are used extensively for the insulation of houses and also to insulate machinery and other types of technical equipment. Different types of mineral wool insulation are available, principally glass wool and stone wool.

A significant proportion of domestic energy use in Europe is expended on the heating of buildings. The application of high quality insulation materials in building roofs, walls and floors could save much of this energy. In addition, both stone and glass wool insulation products demonstrate excellent fire properties, and contribute to improved building safety, and also to the fire safety in many different industrial applications, such as pipes and tanks, and sound insulation products. In both home and transportation applications e.g. domestic refrigeration, ships and trucks, mineral wool is the insulation material of choice.

The main technical feature of any insulation material is high porosity, or large air content inside the structure of the material. This, combined with the required mechanical, moisture, flammability and other specific properties, give the desired low density and thermal conductivity of the product.

In the case of stone or glass wool these specific properties achieved by the use of phenolic based bonding resins specifically developed for this purpose. The mineral wool is first made as raw wool in a specialised high temperature process. The phenolic binder is then applied and the mineral wool is formed into the required shape, such as mats, pipes or slabs with different densities.

In the case of stone or glass wool these specific properties achieved by the use of phenolic based bonding resins specifically developed for this purpose. The mineral wool is first made as raw wool in a specialised high temperature process. The phenolic binder is then applied and the mineral wool is formed into the required shape, such as mats, pipes or slabs with different densities.

Technology

Water soluble phenolic resins are the most common binder used. These resins are easily blended with other components and can be diluted to low concentrations which can be readily applied by spraying onto the mineral wool fibers.

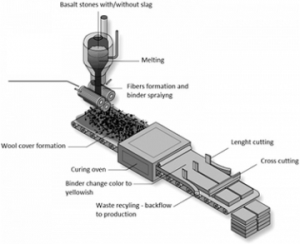

Mineral wool production using phenolic binder systems is typically achieved following a series of processing steps:

- Charge preparation

- Phenolic binder solution preparation

- Silica melt preparation

- Formation of fibres from melt flow of glass or stone. This is normally a proprietary technology.

- Wool mat formed from the individual fibres

- Phenolic binder sprayed to the fibres/mat

- Heating and curing of mineral wool mat

- Cooling

- Cutting into desired forms and sizes and packaging

To achieve the desired properties of the final product careful attention must be applied to the spraying of the binder. Binder formulations should exhibit good flow characteristics to ensure that the binder solution can be applied in low volume and that it will flow deep into the fibre structure and adhere effectively to the loose fibres to provide the required mechanical and elastic properties. Elasticity is particularly important during installation into building partitions on construction sites, consequently the binder adhesion properties at the point of contact with the fibres is important when developing the desired resin system.

To achieve the desired properties of the final product careful attention must be applied to the spraying of the binder. Binder formulations should exhibit good flow characteristics to ensure that the binder solution can be applied in low volume and that it will flow deep into the fibre structure and adhere effectively to the loose fibres to provide the required mechanical and elastic properties. Elasticity is particularly important during installation into building partitions on construction sites, consequently the binder adhesion properties at the point of contact with the fibres is important when developing the desired resin system.

The choice of the binder can affect other properties of the insulation product e.g. density, humidity resistance, VOC emissions during the manufacturing process. The correct choice of binder can significantly reduce, or indeed eliminate, emissions from the insulation material during use.

Resin Requirements

The phenolic resin normally used to bind mineral wool fibres is a highly water soluble resol resin, typically in a 10-15% solution. Urea may be added to form a urea extended resol, which is more cost effective than pure phenolic resin. If the content of urea is increased, a corresponding reduction in product properties is normally observed.

The resin used as the core component of the binder must fulfill several requirements:

- High adhesion to silicate fibres to deliver the high strength properties of the insulation

- Good solubility in water for the formation of optimal-sized particles in the spray emulsion

- High reactivity for curing

- Low toxicity with low or zero VOC emissions

- High heat stability

- Moisture resistance in cured form

- Good aging characteristics to ensure that product properties are maintained over an extended lifespan.

The resins used for binding glass or stone wool fibres, can be divided in two groups. The choice is dependent on cost, processing technology and product performance requirements. The two groups of resins are characterized as follows

- unmodified resins, which require the addition of urea by the insulation wool producer.

- modified resins, which are premixed with urea by the resin supplier and do not need the addition of urea by the wool producer.

Additives used in the preparation of phenolic binders

Ammonia

- pH adjustment to a low alkaline value

Amino silane

- coupling agent to improve the moisture resistance and increase mechanical strength

Urea

- cost effective

- increases fireproof properties

Lignin or lignosulfonate salts

- improve PF/urea blend and reduce costs

Performance

Phenolic resin binders offer an excellent balance between cost and performance for all types of mineral fibre insulation applications, offering exceptional energy saving potential in domestic housing as well as in technical/industrial applications.